The primary goal of any machine building project is to achieve perfectly running production of high-quality products. By leveraging accurate virtual prototypes, seamless production can be ensured earlier in the development process to help assess and improve product profitability.

The increasing complexity of machines requires active management of technical risks in product line development and customer implementation projects. This can be achieved through multiphysics simulation and model-based development to gain a deeper understanding of the phenomena and root-causes of unwanted behavior. Altair’s integrated product and process simulation tools allow a holistic view of the system from different roles to ensure perfectly running production earlier.

Accurate virtual prototyping offers deeper insight into the structures, mechanisms, and machine elements of industrial machinery, but also provides the foundation of AI-driven decision making.

When simulation correlates closely with test data, machine development can be accelerated with numerical optimization to enhance the operational efficiency, eliminate vibrations, and improve machine dynamics.

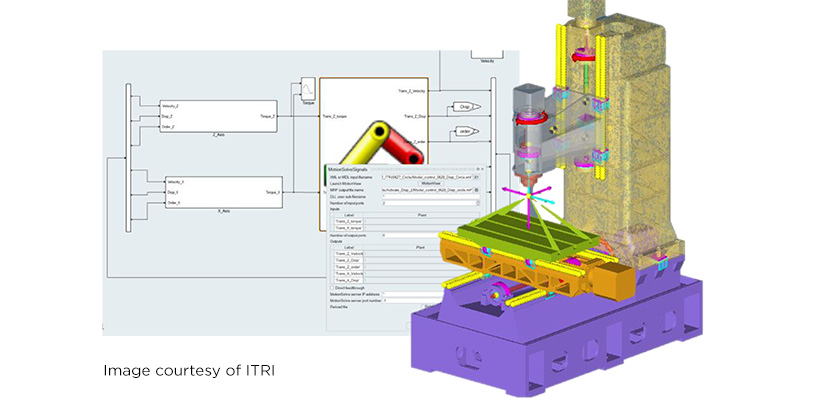

Linking M-CAD, E-CAD, and controls, system simulation can address the challenges of increasingly complex machine generations.

A variety of tools, methods, semantics, and implementations complicate the exchange of necessary information between structural engineers, software engineers, and testing departments. Joining development disciplines with purpose driven simulation, the system development solution Altair® Activate® connects with virtual commissioning environments through the functional mockup interface (FMI) standard. Combining the control sequencing with the actual behavior of the machine allows virtual commissioning and reduces the time investments at the customers facility.

Multi-body simulation, which considers the detailed behavior of machine elements, creates virtual prototypes that provide the basis for numerical optimization, making targeted mass savings and vibration reduction possible. Through multi-body simulation, process accuracy can be achieved faster, improving the productivity of the machine and production line. Detailed multi-body simulation enables life and fatigue evaluations to reduce maintenance intervals due to material fatigue

Machines can be programmed to become self-aware, learning to optimize itself, allowing machine makers to automate path error corrections due to workpiece weights changes, varying manufacturing tolerances, or mechanical aging of the system. Self-learning, automatic path error correction improves part and process quality, increases machine productivity, and reduces tool wear. Control parameter adjustment for speed, accuracy, and surface finish requirements can be automated using integrated electromechanical simulation. Combined with the control system in a holistic system simulation, it allows cause-effect analysis, reduces the adaptation time for control parameters, and creates the basis for machine learning.

A targeted simulation can reveal corrective measures to reduce the noise level in the production facility. Structural optimization can be used to identify cost-effective design alternatives and precise multi-body simulation enables acoustic optimization. With targeted mass savings and mass damping, manufacturers can reduce vibration and determine constructive measures for reducing sound emission.

Consistent lightweight design throughout the machine helps reduce production, processing, and maintenance costs while also cutting production and idle times. Additionally, commissioning lightweight components benefits from reduced loading times on the way to the customer as well as faster set-up time at the customer’s site. Lightweight design results from Altair® Inspire™ and Altair® OptiStruct® consider a variety of manufacturing processes including welded construction, plastic injection molding, sheet metal forming, casting, milling, 3D printing, and more.