To meet the global demand for more sustainable, more sophisticated structures – be they super-tall buildings, protective designs, industrial structures, factories, warehousing, transport infrastructure, communication towers or free-form façade systems – the construction industry is in a transformative period.

The pressure’s on to hasten design processes and improve their accuracy by using simulation tools for structural analysis and to use big data, machine learning (ML) and artificial intelligence (AI) to predict their performance.

When designing and building the world’s most innovative structures, all these challenges and more are solvable through Altair’s world-class design solutions. By accurately modeling and predicting complex structural behavior, wind-induced actions, seismic actions, and other performance factors, we optimize your structure’s performance, mitigate design risks, and ensure you meet code, safety, deadline, and cost specifications.

To help you deliver groundbreaking products on time, Altair offers unique, proven technology breakthroughs to analyze fully-featured CAD assemblies in minutes, eliminating geometry simplification and meshing. With it, you can explore multiple design options – even for your project’s most complex parts and largest assemblies – at lightning speeds.

Altair’s structural engineering solutions ensures your workflow productivity and data integrity with comprehensive data transfer links that manage data during consecutive import/export cycles with building information modeling (BIM) and CAD platforms. In addition, a streamlined workflow performs advanced structural analysis and code performance assessments for different building materials and local design codes.

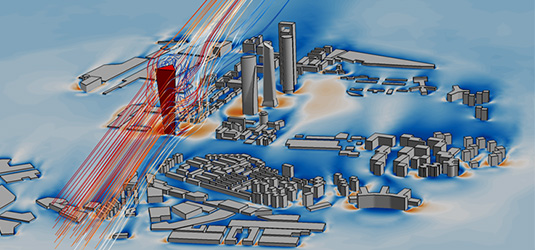

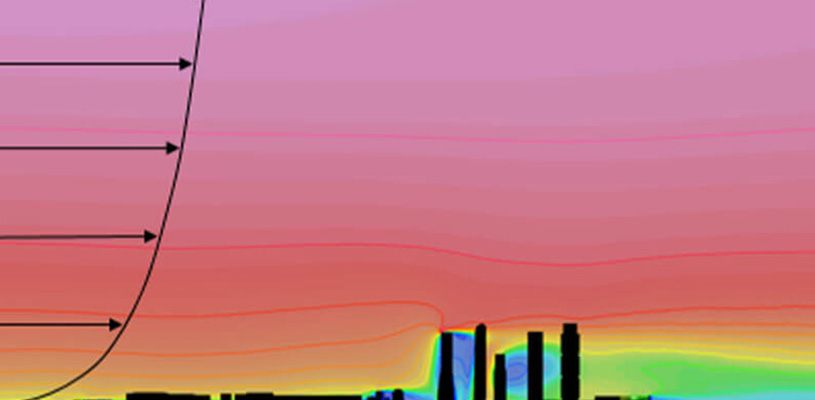

When constructing the world’s largest buildings, it’s imperative to consider the impact of wind pressures on the structure and on pedestrian comfort. Virtual wind tunnel testing is a mature technology that accurately models wind pressures, delivers rapid results, and lets designers explore and evolve concepts based on computational fluid dynamics (CFD) insights.

Altair has developed a multi-disciplinary optimization workflow that helps clients understand structural performance sooner, accelerate design cycles, reduce costs, and validate designs virtually to minimize risk. High-performance design is a holistic, simulation-driven approach for developing safe, feasible, and robust structures.

Altair’s repeatable, customizable workflow combines wind loads with most advanced optimization techniques. Reduce the cost and time to deliver complex steel structures with automatic workflows that integrate all the major AEC structural solvers via direct link or neutral file formats, the power of size optimization for steel sections in 1D models, and topology optimization for 3D models to find the optimal load path.

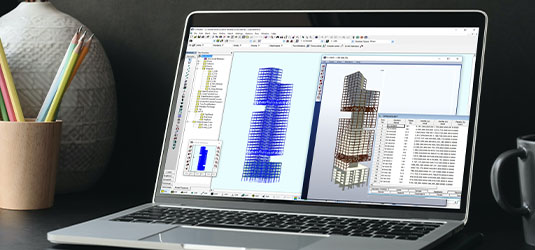

AEC design cycles have two crucial requirements – product performance and timely delivery. Because of immense project pressures, there’s often insufficient time to investigate design alternatives or new solutions. Altair SimSolid™is a technological breakthrough that lets civil engineers analyze fully featured CAD assemblies in minutes, eliminating geometry simplification and meshing. These insights allow engineers to foresee better alternatives in large structural models and evolve designs within existing project timelines. With SimSolid, design teams can perform multiple iterations of their most complex parts and explore multiple alternatives of large assemblies at blazing speed

Altair’s structural engineering solutions ensure streamlined workflows among AEC team members through efficient data transfers during consecutive import/export cycles with BIM, CAD, and 3rd party platforms, providing data integrity while increasing productivity.

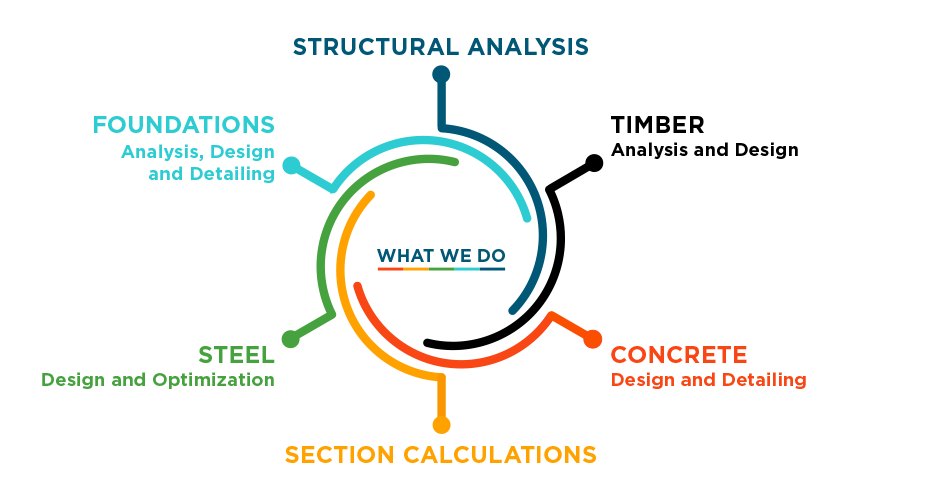

Integrated solutions let you perform advanced structural analysis and code compliance checks for different building materials and regional design codes, reducing the time needed to complete projects. Altair’s AEC analysis and design solutions for everyday workflows include:

Structural Analysis: Evaluate the effects of self-weight, wind, static loads, moving loads, buckling, vibrations, seismic, and other loading conditions on a structure over time through advanced structural analysis capabilities.

Code Compliance: Comprehensive design solutions that ensure code-compliance and reporting to local design codes for steel, concrete, mass timber, and building foundations, including piles.

Concrete Design: The ability to design and detail reinforced concrete and automatically check thousands of concrete structural elements designs at once. Produce detailed design reports that include clause references and intermediate results for regional design codes.

Mass Timber: The ability to efficiently model and analyze complex mass timber and hybrid timber structures, design timber elements (Glulam, CLT, sawn lumber) and generate code-compliant design reports through a timber design solution that utilizes physical element modeling and automated meshing to reduce project time while increasing accuracy.

CFD has become a powerful tool deployed throughout the AEC design workflow. For designers, concept-stage aerodynamic simulation helps shape designs to uphold the client’s vision while adhering to downstream performance targets.

Using digital wind tunnel testing, it’s now possible to investigate multiple design alternatives to determine feasibility and update shapes on the fly. For detailed validation in the latter stages of development, Altair CFD™ provides a granular understanding of aerodynamic phenomenon, mitigating risk, and ensuring safety and stability of the structure.

The Altair technology portfolio includes leading CFD tools that leverage both CPU-based Naiver-Stokes and GPU-based Lattice Boltzmann methods, letting clients select the best method to meet their project’s challenges and requirements.

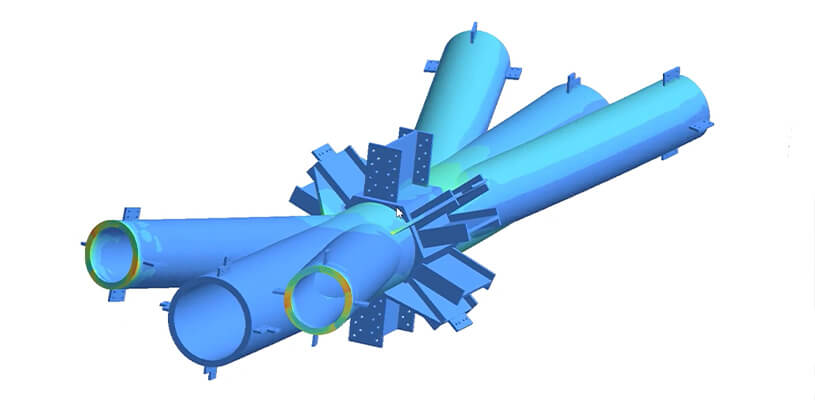

Modern façade system design requires a multi-disciplinary approach that supports all key aspects of façade engineering – structural engineering, thermal analysis, manufacturing, and protective design.

Structural Engineering: Altair’s technology streamlines structural integrity assessments, even for complex parts and large assemblies with hundreds of parts and bolts with pre-tensioning, weld lines, contacts, and friction, and has intuitive tools for both linear and non-linear analysis.

Thermal Analysis: Users can easily calculate energy consumption and thermal effects by leveraging Altair’s suite of CFD Tools

Blast Simulation: Protective design simulation lets civil engineers predict the effects of blasts and explosions on critical structural systems.

Façade Manufacturing: Altair’s manufacturing feasibility software simulates part extrusion profiles, providing end-to-end solutions for façade development.