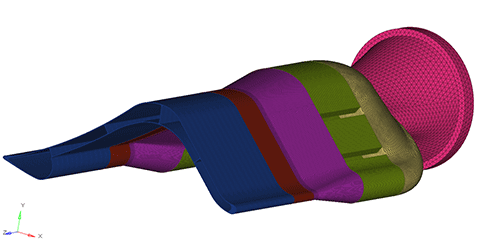

Every extrusion company is looking to eliminate costly prototypes and reduce redesign cycles. Now advanced physics simulations are accessible to organizations of all sizes. Inspire Extrude Polymer is an easy-to-learn tool that enables simulation to be used by any engineer or designer to increase their understanding of how profile features and process variables interact for any particular polymer. It will help your team achieve productivity gains by reducing product development costs and improve extrusion quality, increasing production yield and customer satisfaction.

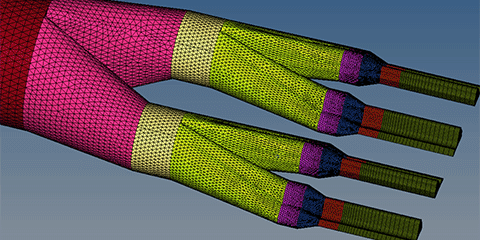

Make better design decisions by detecting potential defects before a die is built. Even the most complex profiles can be validated for production with Inspire Extrude Polymer. Using the geometry creation and simplification tools, CAD can be quickly de-featured and modified inside the tool, ensuring potential defects such as unbalanced flow, overheating profile quality, and poor surface quality issues are corrected early in development.

Using Inspire Extrude Polymer, users can create virtual die trials to determine and eliminate any and all potential issues in die design to help correct them prior to any production or die design.

Identify potential causes of production failure and rectify them upfront to optimize process conditions and increase productivity.

Through a highly intuitive interface, users can benefit from a quick ramp up in detecting extrusion defects early, resulting in both cost and time savings.