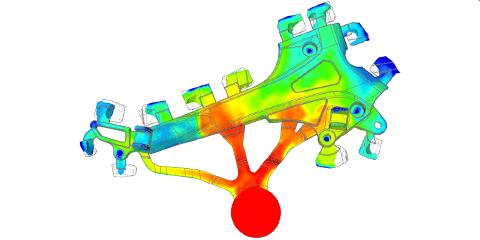

Inspire Cast software is a fast, easy, accurate, and affordable casting simulation environment focused on creating high quality components with increased profitability through a highly intuitive user experience. It is the only tool that caters to beginners and experts alike, from product designers to foundry engineers. Right from early design phase, users can visualize typical casting defects such as air entrapment, shrinkage porosity, cold shuts, or mold degradation and rectifies them avoiding costly downstream corrections.

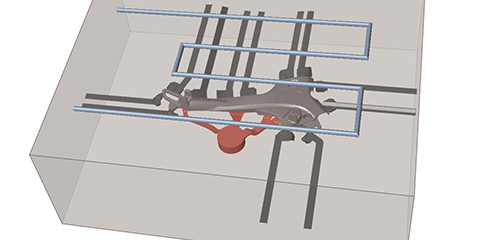

Guided process templates offer five easy steps to simulate gravity die, gravity sand, investment, high pressure, low pressure die casting, and tilt pouring. Inspire Cast’s innovative experience enables users to increase product quality and design better products with a few hours of training.

Radically new designs in combination with new materials demand designers to evaluate their designs early. Engage early with Inspire Cast to simulate possible issues upfront with minimal or no training. As the process gets refined the ability to further investigate and optimize the process makes Inspire Cast uniquely valuable during the entire product development cycle from early design to manufacturing.

In industry, it is usual to simulate a process after it has been designed. Inspire Cast turns this concept upside down, helping users develop the process along with their ideas. It guides the user through issues of porosity and compensation risers. It has process templates for die casting and sand moulds, lost wax, high and low pressure casting or tilt pouring.

State of the art, bi-phasic finite element formulation allows for capturing the filling and solidification process with great precision. This helps with building great quality castings with high margins.