The automotive industry is experiencing dynamic technological advances that affect all aspects of car manufacturing, from design concepts to the product coming off the line. One of the critical factors revolutionising the sector is advanced simulation software. Altair is a leading company providing this type of solution. It introduces innovative products and services, supporting the transformation of modern vehicle design.

Past, present, future

Altair is a global technology company dedicated to providing advanced engineering solutions and simulation software to various industries, including the automotive industry. Since its inception, the company has sought to develop tools that enable engineers to design, analyse and optimise products more efficiently and accurately.

A revolution in car design

Traditional car design methods relied on physical prototypes, which were costly, time-consuming, and limited in capabilities. The introduction of simulation software has given designers the tools to virtually test and optimise vehicles at every stage of the design process. Altair offers a range of specialised software to comprehensively test how materials, systems, and entire vehicles will behave under varying conditions.

Programmes:

Altair® OptiStruct®: Minimising weight, maximising strength

OptiStruct, developed by Altair, is a tool that enables designers to reduce component weight while maintaining strength. Thanks to advanced optimisation algorithms, designers can find optimal shapes and geometries that reduce component weight while providing adequate strength. This, in turn, creates lighter, more efficient, and environmentally friendly cars.

Altair® MotionSolve®: Virtual modelling of vehicle movement

MotionSolve is a tool that allows the virtual modelling of vehicle movement. Instead of building physical prototypes, designers can use it to create virtual models and simulate different movement scenarios, such as braking, turning or driving over bumps. This allows potential problems with vehicle dynamics to be identified and leads to improvements in performance and safety.

Altair® EDEM™: Simulation of material interaction

Edem is a tool for simulating the interaction between materials, such as loose ground (e.g. sand or gravel) and vehicle components. In the context of vehicle design, this allows analysis of whether individual components can withstand loads and fatigue tests. This is key to ensuring vehicle durability and reliability and minimising the risk of failure.

Altair® HyperLife®: Optimisation/fatigue strength testing

HyperLife is a tool for testing the strength and durability of components, including welds and fasteners. Not only does it enable designers to identify structural weaknesses, but it also allows certification of parts against applicable standards.

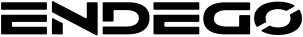

Altair® Radioss®: Virtual crash tests

Radioss Radioss is a tool for conducting virtual crash tests. Rather than destroying physical vehicles, designers can use it to simulate different scenarios virtually, resulting in more efficient and cost-effective safety tests. Radioss supports every stage of the design process, from design to production to crash testing.

Altair® SimLab®: Rapid analysis

SimLab is a handy tool in the early stages of design. It allows designers to carry out rapid strength analyses.

Altair® Flux®: Design of electric motors

The electrification of vehicles is becoming increasingly important. Altair Flux is a tool that allows the design and optimisation of electric motors. This enables designers to create effective, efficient and powerful drive units that meet the requirements of modern electric cars.

Altair® Inspire™ Form iAltair® Inspire™ Cast: Innovative casting and sheet metal stamping processes

Inspire Form is a programme designed to simulate the sheet metal stamping process. Its advanced algorithms analyse the behaviour of materials during the forming process, allowing potential manufacturing defects to be predicted. In the case of sheet metal stamping, where dies are costly, this programme enables potential problems to be detected before actual production occurs. Inspire Cast works well in casting, such as producing engine blocks. Inspire Cast allows surface defects, cracks, or other potential problems to be detected in advance.

Altair® NanofluidX: Investigating the interaction of liquid materials

NanofluidX is a tool that enables the study of interactions between different fluids, for example, in an oil splash situation in a gearbox. With this programme, designers can simulate the behaviour of various substances under varying conditions, allowing them to accurately predict their interactions and potential problems.

Altair® Inspire™ Studio: Realistic animations from analysis

Inspire Studio is a program that allows the creation of realistic animations based on the results of simulation analyses. It will enable designers to see a visualisation of how a component behaves under different conditions or loads. This not only makes it easier to understand the results but also allows this information to be communicated in a way that is more accessible and understandable to all involved in the project.

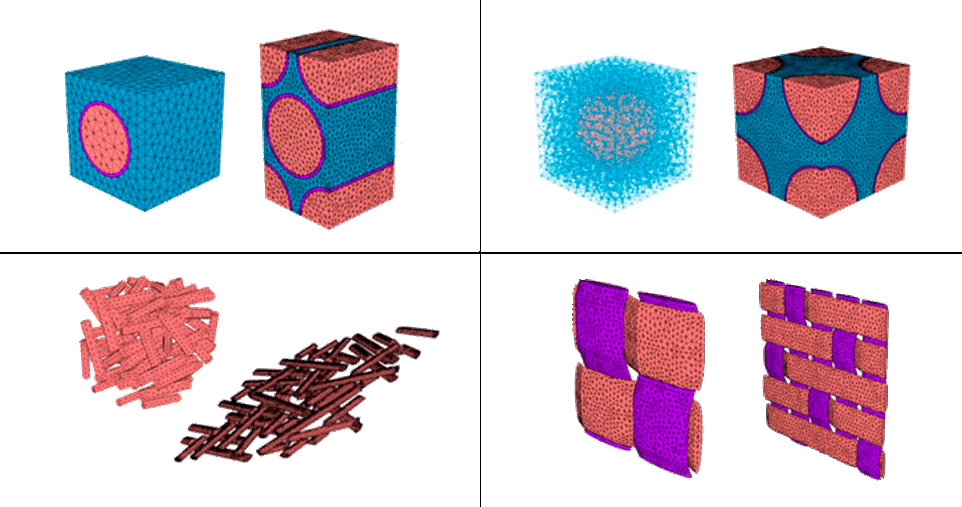

Altair® Multiscale Designer®: Modelling complex materials

Multiscale Designer is a tool that enables the modelling of complex, heterogeneous materials. In the case of the automotive industry, where various raw materials are used, including composites or hybrids, this programme becomes essential. It allows an accurate understanding of the behaviour of diverse materials, resulting in improved vehicle performance, durability, and innovation.

Benefits of Altair software

1. Shortening the design cycle: Altair software allows the creation of virtual car models that can be tested for performance, durability, aerodynamics, and other vital parameters. This reduces the time it takes to create a vehicle from concept to production.

2. Cost reduction: Eliminating the need for multiple physical prototypes translates into significant cost reductions. Altair’s software enables the simulation of various conditions and scenarios, allowing potential problems to be identified and eliminated while still in the design stage.

3. Performance optimisation: Through numerical analyses, designers can improve vehicle parameters such as aerodynamics, fuel consumption or energy efficiency. This translates into more environmentally friendly and economical cars to run.

4. Safety and innovation: Simulation software allows cars to be tested under various conditions, including emergencies and accidents. This makes it possible to design safer vehicles and test innovative solutions such as autonomous driving systems.

The future of car design with Altair

Altair simulation software is vital in revolutionising how today’s cars are designed. Thanks to technological advances, car designers can now access tools and solutions that enable even more efficient and innovative vehicle design. Altair software speeds up the design process, optimises components for efficiency and ecology, and integrates advanced technologies such as artificial intelligence and data analytics. This all translates into more efficient, safe and environmentally friendly cars. The use of Altair software is the path to a more sustainable, innovative and exciting future for the automotive industry, whose creations will meet the expectations of customers around the world.